China Wholesale Induction Bends Pipeline Suppliers - Factory supplied China Milling Welding IGBT Induction Heating Equipment Welding Generator – Duolin

China Wholesale Induction Bends Pipeline Suppliers - Factory supplied China Milling Welding IGBT Induction Heating Equipment Welding Generator – Duolin Detail:

The really abundant projects management experiences and 1 to just one provider model make the high importance of business enterprise communication and our easy understanding of your expectations for Factory supplied China Milling Welding IGBT Induction Heating Equipment Welding Generator, For more information and facts, you should never wait to make contact with us. All inquiries from you may be highly appreciated.

The really abundant projects management experiences and 1 to just one provider model make the high importance of business enterprise communication and our easy understanding of your expectations for China Induction Brazing Machine, Induction Solding Machine, It is our customers’ satisfaction over our products and services that always inspires us to do better in this business. We build mutually beneficial relationship with our clients by giving them large selection of premium car parts at marked down prices. We offer wholesale prices on all our quality parts so you are guaranteed greater savings.

Products Description

| Certification | CE ISO9001 2105 |

| Brand | Duolin |

| Warranty | 1 Year |

| Production capacity | 10 set one month |

| HS Code | 8514400090 |

1:100-160 KW Induction Heating Equipment adopts the IGBT inverter circuit in series connection, which has high heating efficiency

2. High power, fast heating speed, high efficiency and easy operation.

3. The comprehensive full load design is available for 24-hour continuous operation.

4: 160KW IGBT Solid state induction converter, the cabinet is well sealed, no failure and IGBT never burst.

5: Application: Hot forging, Shrink fitting, smelting, surface quench, welding, annealing

6:High conversion efficiency more than 97.5%:IGBT(Insulated Gate Bipolar Transistor)inversion technology

7:Energy saving up to 15%-30% compared with SCR technology induction machine:LC series resonance circuit and voltage feedback design, low energy comsumption

8:Cooper &stainless steel fasteners and radiator,better cooling and anti-electrolysis

Application

1.Preheating (billet hot forging, shrink fitting)

Billet Hot forging aims to heat the work pieces to certain temperature (different materials require different temperatures) into other shapes through forging press with the help of hot stamp or press machine, it can be full or end or head heating of bar,usually use for fastener bolts and nut and other metal related manufacture industry

2.Shrink fitting:Shrink fitting is a heating process to heat metal material creates an interference fit. The increase in hole size allows the insertion or removal of a mating components after heating and cooling.Thank to fast heating speed of induction,temperature can be controlled exactly,prevents distortion and needed metallurgical changes,the thermal expansion creates a joint,gear to shaft,flanges to hubs and bearing insertion are common for shrink fit.

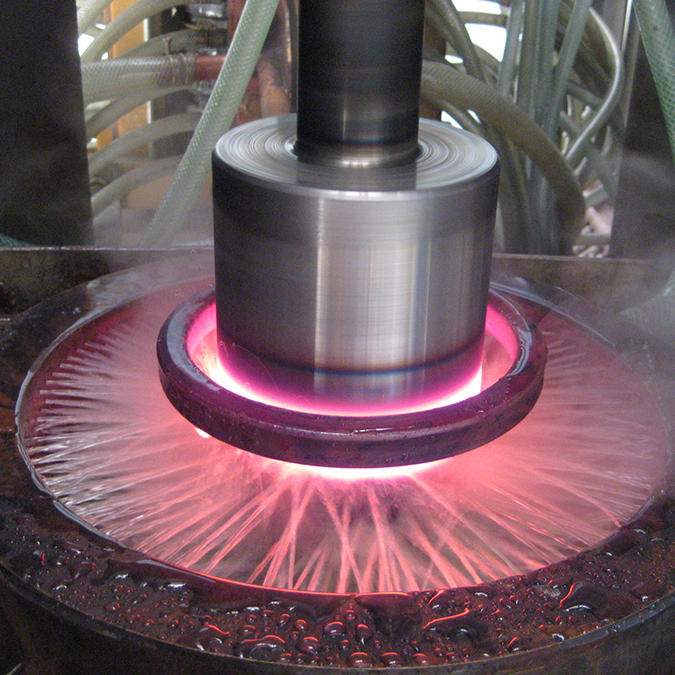

3. Heat Treatment (surface scanner )

Heat treatment for various hardware or tools, such as plier, wrench, hammer, ax, screwing tools and shear (orchard shear).

Hardening for auto part and motorcycle fittings, such as crankshaft, connecting rod, piston pin, chain wheel, pump fitting ,valve, axle shaft, small shaft or steel bar and kinds of gear

Quench for machine tools, such as lathe deck or guide rail.

Induction hardening for hardware molds, such as small-size mold, mold accessory and inner hole of mold

Long bar or thread bar induction hardening and tempering, fully automatic production line

4. Brazing

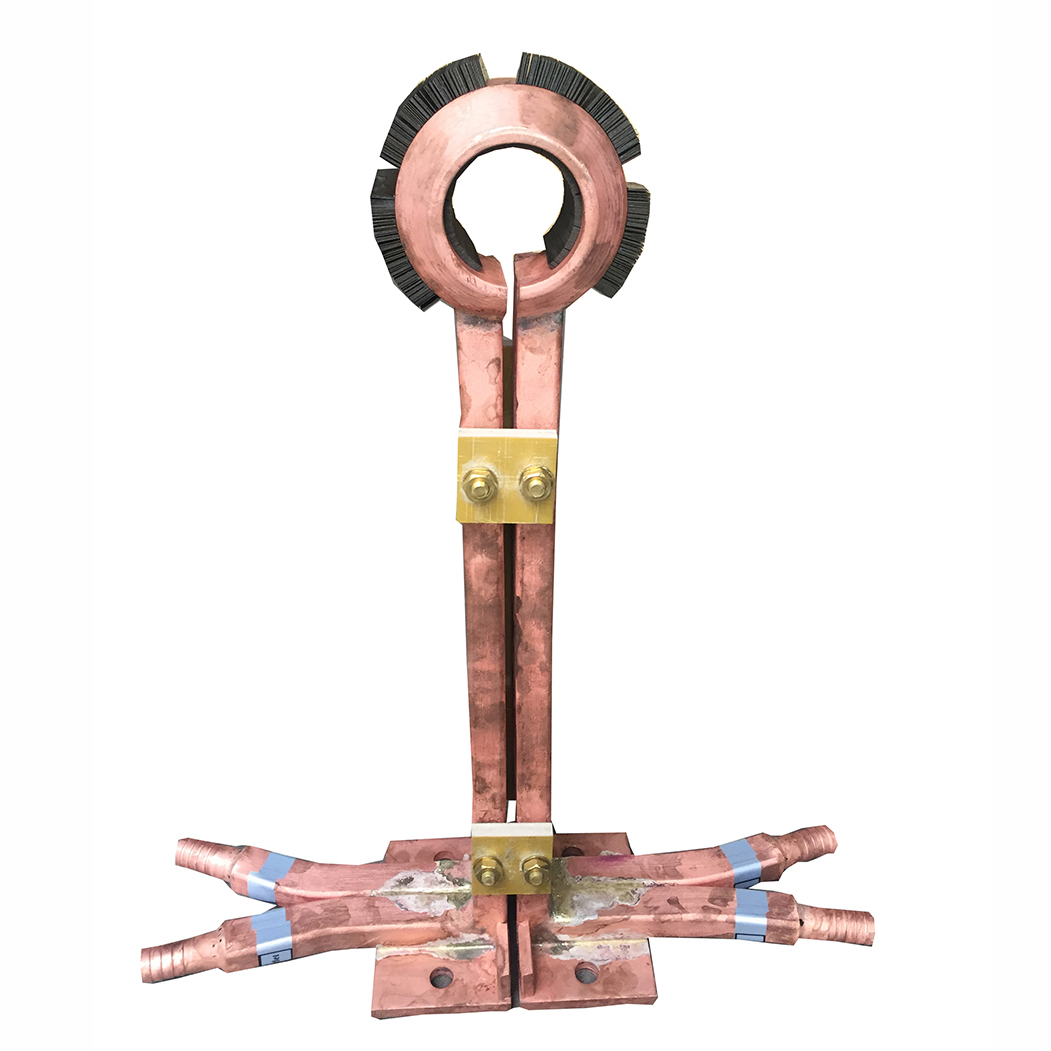

Induction heating of brazing for kinds of hardware cutting tools, such as diamond tool, saw blade, drilling tool, hard alloy steel cutter, milling cutter, reamer, planning tool and solid center bit and rotor induction brazing

The brazing media are different when materials are not same,Silver is the most common,the soldering part are hardware toilet and kitchen products, refrigerating copper fitting, lamp decoration fitting, precision mold fitting, hardware handle, eggbeater, alloy steel and steel, steel and copper as well as copper and copper.

It is also applicable to plain braze welding of other metals.The really abundant projects management experiences and 1 to just one provider model make the high importance of business enterprise communication and our easy understanding of your expectations for Factory supplied China Milling Welding IGBT Induction Heating Equipment Welding Generator, For more information and facts, you should never wait to make contact with us. All inquiries from you may be highly appreciated.

Factory supplied China Induction Brazing Machine, Induction Solding Machine, It is our customers’ satisfaction over our products and services that always inspires us to do better in this business. We build mutually beneficial relationship with our clients by giving them large selection of premium car parts at marked down prices. We offer wholesale prices on all our quality parts so you are guaranteed greater savings.

Product detail pictures:

Related Product Guide:

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of China Wholesale Induction Bends Pipeline Suppliers - Factory supplied China Milling Welding IGBT Induction Heating Equipment Welding Generator – Duolin , The product will supply to all over the world, such as: Milan, kazakhstan, Mauritius, By continuous innovation, we will provide you with more valuable products and services, and also make a contribution for the development of the automobile industry at home and abroad. Both domestic and foreign merchants are strongly welcomed to join us to grow together.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!