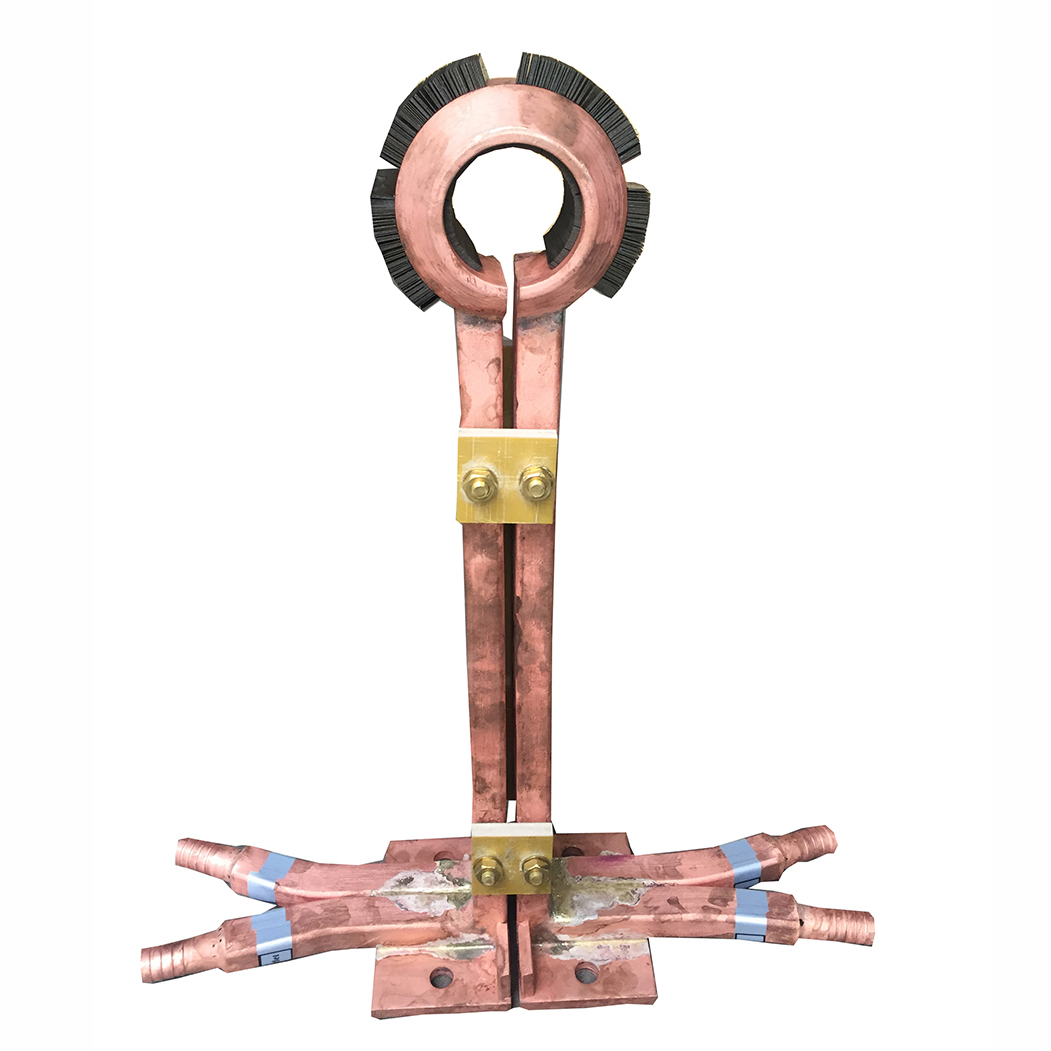

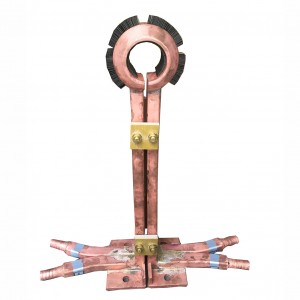

Induction coil&Inductor

Products Description

Duolin designs and produce custom induction coils. Induction coil is the output work head of the induction heating system, also called inductor. Induction coil use to connect the induction heating machine with the heating workpiece,it is made of cooper tube usually,can be use for induction hot forging,brazing,induction quenching and pipe bending….

Induction coil is a critical component of the induction system. Coil’s inductance should match with heating machine, to achieve best heating efficiency and biggest output power. Copper tube wall thickness and OD are important parameter to make good inductor.

Features

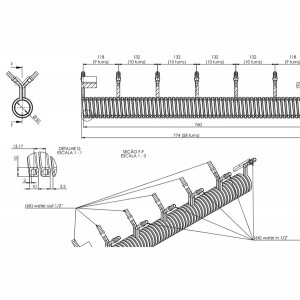

1: Quick change coil connector, reduce the machine down time

2: Coils are protected from high voltage with insulation material or safe covers

3: Water cooled copper tube increase the coil service time

4: Quenching coil with water spray integrated

5: Custom designed coil for billet heating, improve the heating efficiency

Duolin has induction heating coil shop, we can test as your heating requirements, no matter what the heating application is, Duolin team will find suitable coil and induction heater for testing to help customer choose the correct induction heating solution.