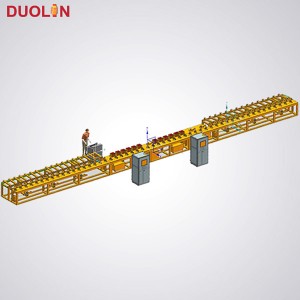

Induction bending machine

Products Description

Induction pipe bending process uses induction coil heats a narrow, circumferential section of the pipe to a temperature 850-1100 degrees Celsius (dependant on the material to be formed), the pipe is moved slowly through the induction coil whilst the bending force is applied by a fixed radius arm arrangement.

Induction hot bender is known for its high quality, accuracy bending and cost savings. Induction bends provide bending of large sections - particularly pipe and other hollow sections, widely used for Roadway signage, Construction (structural shapes), Pipeline for oil & gas (on and offshore), Hot water pipes, Pipeline for chemical raw material, Pipeline for electric wires.

Induction Bend is perfect for these industries:

●Highway billboards

●Structure construction

●Oi and gas (onshore and offshore) pipelines

●Chemica and petrochemica pipelines

●Shipbuilding

Bending type: Pipe, Square tube, Rectangle tube, Beam

Material:

● Seamless tube: 20G、 A106B、A106C etc.

● Longitudinally welded pipes:235B、345B、X42、X52、X60、X70、X80 etc.

Alloy steel:335P12、P22、P91、12Cr1MoVG、WB36 etc.

Feature

1: Keep a constant heating temperature when bending,Ensure the physical characteristics of bends or elbow.

2: The latest technology IGBT inverter technology,series resonance,more energy saving than Diode rectification,and don’t need capacitor cabinet

3: Power factor is not less than 0.95

4: Phase lock technology and automatic frequency tracking make the machine work more efficiently.

5: Precisely heating and bending,better quality bends or elbow,more cost saving

6: Can bent in different ways,square tube,rectangular tube and angle steel can be bent

7: Low installation and operation cost

8: Not require sand filling and internal mandrels

9: Superior quality at ovality and wall thinning

10:PLC control to set and store each pipe bending process parameter

| IGBT Induction Bending Machine |

Capacity |

| Induction Bending Machine 168 |

168 x 13 |

| Induction Bending Machine 325 |

325 x25 |

| Induction Bending Machine 426 |

426 x30 |

| Induction Bending Machine 530 |

530 x 30 |

| Induction Bending Machine 630 |

630 x 30 |

| Induction Bending Machine 720 |

720 x 35 |

| Induction Bending Machine 810 |

813 x 35 |

What we need to know before offer pipe hot bender solution?

1: The pipe material length wall thickness and OD

2: Bending radius and angle

3: For elbow or hot bender

4: Bending production

5: The usage of pipe,for gas oil or other industry

6: Require for ovality and wall thinning