-

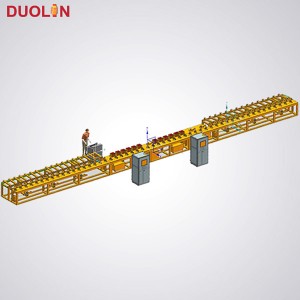

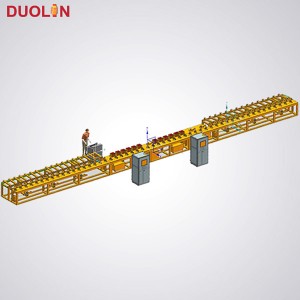

Induction bending machine

Induction heating for pipe bending

Bending pipe: Diameter 168mm-1100mm, wall thickness 6-80mm

Power output: 100-1500KW

Bending Type: Pipe, Square tube, Rectangle tube, Beam

Material: Carbon steel, stainless steel, alloy steel

Bending speed: Around 2.5 mm per minute

Bending angle: 0-180°or set any angle

Bending Radius:3D≤ R≤10D

-

induction hardening machine

DUOLIN offers induction vertical or horizontal hardening machine used for hardening a wide range of mechanical parts, such as shafts, gears, rollers, pipes, pump fitting, bearing, excavator teeth, etc. DUOLIN provides you customized induction hardening solutions for you particular job, maximize your benefits.

-

Long bar heat treatment machine

Application: Continuous hardening and tempering

Part: long bar, threaded rod

Size: 6-100mm

Length: 1000-14000

Grade: 8.8, 10.9, 12.9

Material: Carbon steel, alloy steel

-

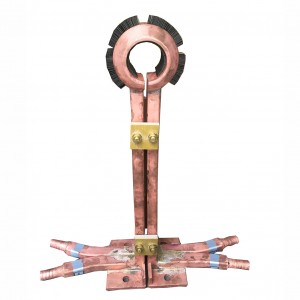

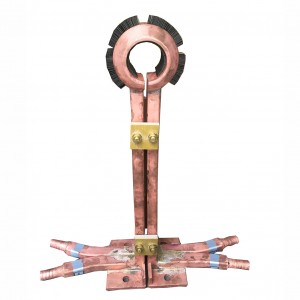

Induction coil&Inductor

With induction heating system,coil design will responsible for engineer who have more than ten year of experience in coil making.How to choose copper coil size?make suitable inductance coil to match with machine,how to improve the heating production?how to output the max power?engineer will consider all the factors.

Send us your heating requirements,for hardening forging,brazing or other application,also send us the drawing of heating parts,we will design and produce coil for you.

-

High frequency induction heating machine HFP-20

Good performance at heat treatment and wire heating

For saw blade and carbide tips machine tool and other small parts copper tube induction soldering

Can be use for gold silver induction melting

Repeatable reliable heating efficiency and versatile

-

High frequency induction heating machine HGP-50

For gear shaft pin induction hardening,depth 0.5-2 mm

For chain induction heat treatment,hardening and tempering

-

Ultrasonic frequency induction heating machine

IGBT inverter used,high efficiency and low energy consumption

Can work continuously with 100% duty cycle and set up 100% at any load

Can replace convention heating method such as heating by flame coal salt bath gas and oil

Work frequency 10-30Khz,power 30-250KW

Digital display and compact design,light weight,easy for installation and operation

Soft switch technology and prefect protection system enhance good reliability.

Can equipped with infrared temperature detection system (Optional)

Water cooling system ,chiller is available

-

Closed type

Cooling water shall be free from impurities. DOT NOT use well water or river water .To prevent the scale formation, ensure good cooling result, and greatly reduce the failure rate,Soften Water or Distilled Water are strongly recommended as cooling water for induction equipment.

-

Integrated Induction Power Unit

Good reliability: Perfect protection system, reliable components, soft switch technology

Easy to operate and maintain: Module design and simple circuit construction

Application in Forging,Heat treatment,Pipe bending,Hot extrusion,Braing,Shrink-fittin,Hardening etc

Produced under ISO9001:2015 and CE certificate

Integrated design, less installation space

-

250KW induction heater

250KW induction heating equipment with low frequency is good for big diameter billet heating and deep surface hardening.

Drive board and IGBT connected directly, shorten signal transfer to reduce failure rate

All fasteners are copper &stainless steel

More water temperature&pressure monitoring,copper radiator for better cooling and anti-electrolysis

-

low frequency induction heating equipment

Good start up performance:IGBT MF induction power supply apply series resonance technology so it can be starts up 100% under any condition.

Less indterface to power grid:Less harmonic current and high power factor,Power factoer remaining 0.95 above during machine running

Low energy consumption: in series resonant circuit,voltage at inductor high and current low so energy loss is very low ;Soft switch technology applied then switch loss is very low

-

100-160KW low frequency induction heating generator

Duolin engineer team research and design separately. Machine can be used for hot forging,induction soldering, hardening and other metal related induction heating.

Easy operate work panel to show the induction equipment work condition.

LED lights to show the PCB board work,easy to find the problem and repair.

1 More than 20 years of experience in induction heating industry.

2 Free test for choosing the machine model before purchase.

3 Product design research develop and maintain by the Duolin Engineer team,machine lifetime service.

4 Test the machine as customer heating requirements and aging more than 6 hours to guarantee the good quality.

5 Offer installation manual and troubleshooting guide .

6 Use famous brand components Infineon Omron Schneider to ensure quality of material

2 Free test for choosing the machine model before purchase.

3 Product design research develop and maintain by the Duolin Engineer team,machine lifetime service.

4 Test the machine as customer heating requirements and aging more than 6 hours to guarantee the good quality.

5 Offer installation manual and troubleshooting guide .

6 Use famous brand components Infineon Omron Schneider to ensure quality of material